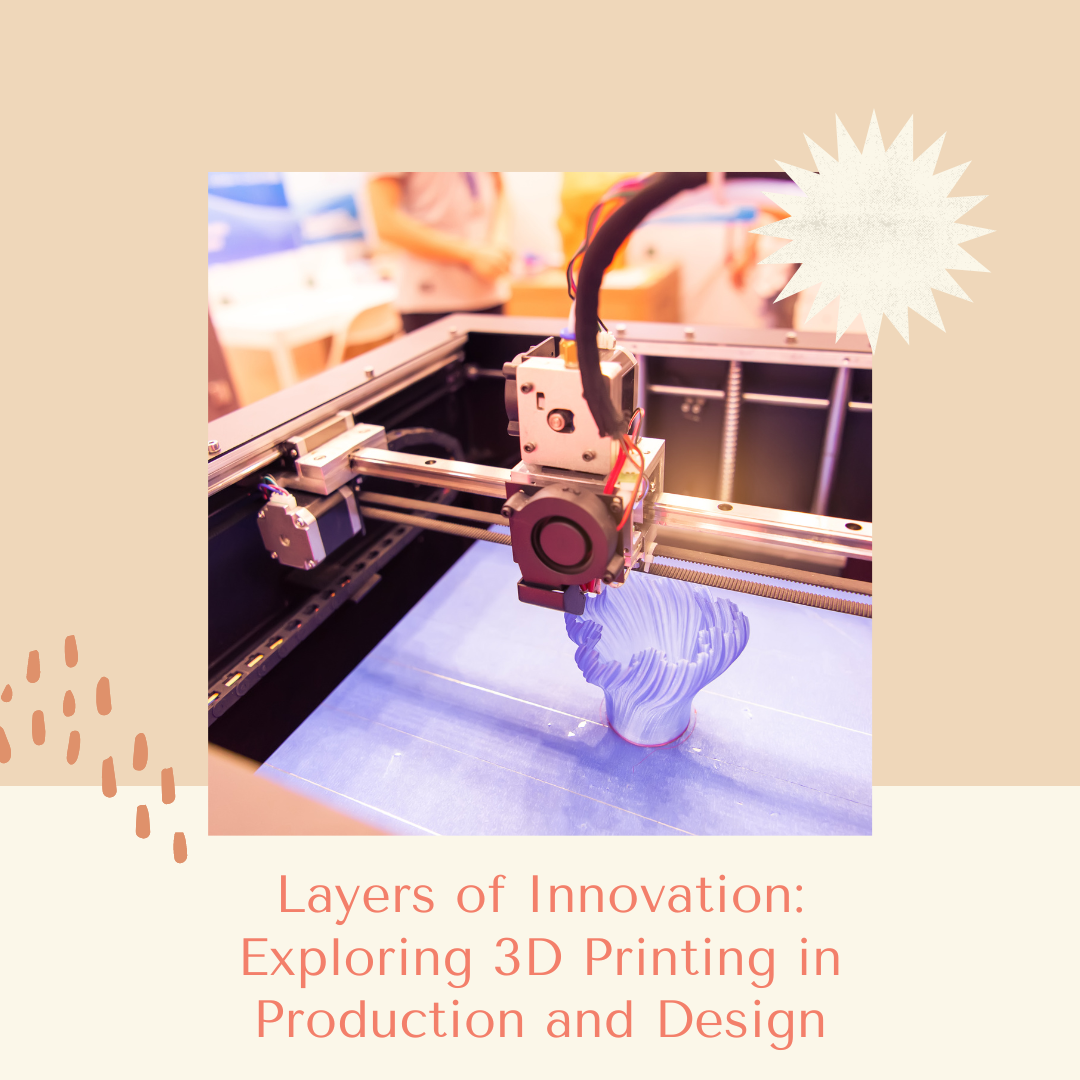

The realm of 3D printing holds immense potential, revolutionizing the way objects are created and designed. This innovative technology, also known as additive manufacturing, has gained widespread attention across industries.

In this article, we will take a closer look at the fascinating process of 3D printing, delve into key print settings, and understand how this groundbreaking technology is reshaping production and product design. The 3D Printing Process: At its core, 3D printing involves a meticulous layer-by-layer construction process.

Let's explore the steps involved:

1. Digital Modeling: The journey begins with a digital 3D model. Skilled designers create these models using computer-aided design (CAD) software, or they can be obtained through 3D scanning technologies that capture real-world objects and convert them into digital form.

2. Slicing: The digital model is then sliced into hundreds or thousands of ultra-thin layers using specialized software. Each layer represents a cross-section of the final object and dictates the printer's instructions.

3. Print Settings: Before commencing the print job, various settings need to be configured

- Material Selection: Different materials such as plastics, metals, ceramics, or composites can be used based on the desired properties and characteristics of the final product.

- Layer Thickness: The layer thickness determines the level of detail and smoothness of the printed object. Thinner layers result in finer resolution but longer print times, while thicker layers are quicker but may compromise detail.

- Print Speed: The print speed determines how fast the printer moves and deposits the material. Higher speeds reduce print time but may impact print quality, especially for intricate designs.

- Temperature Control: For certain materials like thermoplastics, maintaining an optimal temperature during the printing process is crucial for ensuring proper layer adhesion and structural integrity.

- Support Structures: In cases where overhanging features or complex geometries exist, support structures may be added during printing. These temporary structures provide stability during the print and are removed once the object is complete.

4. Printing and Post-Processing: with the settings in place, the 3D printer springs into action. It carefully deposits or solidifies the material layer by layer, following the instructions from the sliced model. Depending on the complexity and size of the object, the printing process can take minutes to several hours or even days. After printing, post-processing steps such as removing support structures, sanding, polishing, or painting may be performed to achieve the desired finish.

Applications of 3D Printing: The versatility of 3D printing spans a myriad of applications, including:

- Rapid Prototyping: 3D printing enables swift and cost-effective prototyping, allowing designers to iterate and refine their concepts at a fraction of the time and expense of traditional methods.

- Custom Manufacturing: The ability to create highly customized and personalized products sets 3D printing apart. From custom-fit medical devices to tailored consumer goods, this technology empowers individuals to have unique and precisely tailored items.

- Small-Scale Production: With advancements in print speed and reliability, 3D printing is increasingly being used for small-scale production runs. It offers agility, reduced lead times, and cost-effective manufacturing for niche markets and specialized products.

- Education and Research: 3D printing serves as a powerful educational tool, providing hands-on learning experiences and facilitating the creation of intricate scientific models. It also supports research in various fields, enabling the production of prototypes, anatomical models, and specialized components. Conclusion: 3D printing has ushered in a new era of production and product design, redefining what is possible